Production of designer cardboard boxes

In modern business, packaging plays a key role in forming the first impression of a product and brand. ATTOLIS company creates packaging solutions that will help you present your product favorably and stand out among competitors: designer cardboard boxes will be an excellent solution. Any idea can be effectively implemented taking into account all the requirements and wishes of the customer – and an experienced team will cope with this task perfectly.

What designer packaging can I order

Product options, including binding cardboard packaging, are quite numerous. For any category of goods you can choose a suitable solution: souvenirs, products, gift sets, cosmetics, sweets, perfumes. This is an excellent combination of stylish design and practicality, due to which the products will be reliably protected from external influences and damage. You can order boxes made of designer cardboard in various variations:

- retractable – the main element slides out from the inner drawer, which looks elegant and creates a surprise effect;

- with double bottom – an additional layer at the bottom hides the internal components and will also act as a shock-absorbing layer, which is important for transporting premium goods and fragile items;

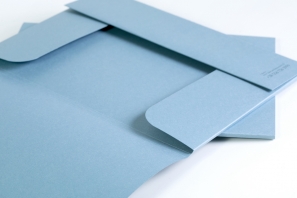

- with a hinged lid – designer gift boxes provide convenient access to the contents, and most importantly allow you to demonstrate goods to a potential buyer without compromising the integrity of the design;

- lid-bottom – consist of two separate elements, which makes the packaging easy to open and close, making it a universal option for most products;

- on magnets and tapes – original clasps not only securely close the box, but also give it sophistication;

- with supports – production of cardboard packaging with internal inserts that create separate sections for convenient placement and protection of goods, which protects products from damage during transportation time.

To order boxes with an individual design, you need to provide detailed information about the products intended to be placed in them: its dimensions, properties, purpose and key features. Based on this, managers will select the type of packaging container and also offer interesting design ideas that will look most advantageous.

Digital printing ATTOLIS offers digital full color printing for branding cardboard boxes for honey jars, sweets, cosmetics, soaps and other products of suitable size. We produce such packaging in small and medium runs. Pros: Silk-screen printing Today the technology is widely used in the printing industry. ATTOLIS company performs silk-screen printing on paper, cardboard, corrugated board, plastic and other materials. Features You can create an image using one color or several different colors, you can make a metallized or fluorescent image. For each color, its own stencil grid is created, the cost of silk-screen printing depends on the number of printing colors. Offset printing Today this technology is widely used in printing houses. ATTOLIS offers qualitative offset printing on boxes and packaging. Our experts will impliment any ideas of the client, make an unusual design for an individual order. We use offset printing to produce full color, durable corrugated boxes. Printing is not applied directly to corrugated cardboard, but to cardboard sheets. We use the laminating method on our special equipment - we glue cardboard with full-color offset printing to corrugated cardboard, cut it to shape, fold ready-made durable colorful boxes. Features Pros: Embossing ATTOLIS has all the necessary equipment for foil stamping and hot stamping, which allows us to implement different customer ideas in packaging decoration. When processing foil stamping, a foil is laid and pressed between the metal plate and the material, a metallized imprint remains on the material. For stamping we can use foil: Dyed embossing, i.e. embossing on print, is often used for the production of branded packaging. Additionally, selective UV varnish can be used, then the print will be even more voluminous. Features For one relief print 2 cliches are needed, which will compress the material from the front and back sides. The demand for this type of printing services is constantly growing in the field of business and advertising. Often in the manufacture of packaging and printing, printing is not used at all, all images and texts are applied by hot stamping and foil stamping. In addition to relief stamping and foil stamping, we also perform Silk Foil stamping without clichés. Silk Foil allows us to get an eminent image in the color of bronze, gold, silver, which is not depressed on the back. UV Coating In case of packaging branding by application of spot UV coating, the logo is applied with a transparent ultraviolet material, which makes it possible to highlight the brand name, gives it an overflow effect, but does not make it too catchy. To obtain a more colorful image, the logo can be printed by offset or digital printing with further UV varnish coating. An embossed, tactilely perceptible picture is provided by applying a "high" UV varnish. UV varnish can highlight not only the logo, but also other elements: illustrations, lines, company name. Adding glitter to the varnish allows to obtain a glitter material that will provide shine and attractiveness to the packaging design elements. Features Also UV-varnish can be matte - Soft Touch coating gives velvetiness to surface of printed products. The application of a special varnish provides: The use of UV varnish allows to create truly exclusive products.

Digital printing - transferring an image onto cardboard or paper using a laser, inkjet printer or printing machine. Application of paint directly to the sheet does not require longtime and expensive preparation. It is the ideal solution when for producing small runs of compact packaging boxes under tight deadlines.

Minuses:

Silk screen printing is a modern type of screen printing, which is performed using a special mesh. The thick paint under the pressure of the squeegee hits the surface through the holes of the mesh, on which the stencil of the future image is created. The print is dried with hot air and special lamps.

The screen-printing method is used for branding the packaging, applying prints, text, illustrations. This method allows you to obtain clear, high-quality printing keeping the original color of the image at the background of any color. So the brand logo printed on the cardboard packaging will remain in the corporate color, no matter what shade the background of the packaging is. Silk screen allows you to apply matte, glossy, complete or spot UV varnish.

Offset printing is a technology that involves applying an image to paper or cardboard by transferring it through special rollers. This method requires significant time and money, but the image quality is high.

Offset printing guarantees accurate color reproduction, contrasts and smooth color transitions.

Minuses:

Embossing is a creation of a sculptured image on a printed material by compressing it between cliches. Cliches for embossing are made according to the layout, in cliches the necessary shapes are cut out, they will leave an impress on paper or cardboard. The relief of the image can be eminent on the front side (embossing), or depressed (debossing).

For embossing, it is necessary to order the production of metal forms (cliches), their cost is calculated depending on the area of the embossed elements.

UV coating technology gives printed products a gloss and matte finish without lamination. Matte or glossy varnish can be applied to the entire surface of the product or selectively to make certain elements more noticeable.

Ultraviolet varnish has a high gloss, dries quickly, and is resistant to chemical and physical stress.

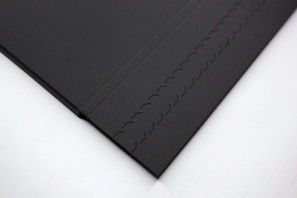

Advantages of packaging made from designer cardboard

The main advantage of designer cardboard is its high quality and presentable appearance. Black packaging made from black designer cardboard and regular cardboard with black printing will be different. In a package made of designer cardboard, the entire volume of material, including the ends, will be black, since this cardboard is completely colored in the mass, which cannot be achieved from ordinary cardboard printed black; the ends of such cardboard will remain white. In addition, designer cardboard has variations in surface structure; it can be matte, glossy, rough, with a soft touch effect, or embossed. The cardboard densities also differ.

There is a large selection of designer cardboards, you can definitely find one that suits your brand.

Various types of processing and branding are used on colored and structured cardboard:

- Foil stamping. You can choose matte, glossy or holographic foil to apply your logo, graphics, texts to the packaging. This design always looks premium and increases the value of the brand.

- embossing. This is the application of a relief image without color; a voluminous depressed or convex image remains on the material - laconic and very stylish.

- silk screen printing. With the silk-screen printing method, a color imprint remains on the material without color distortion, even on the darkest and most colorful material

- UV varnish application. UV varnish can be applied over the printed image or onto the material itself without printing. You will also receive a laconic and stylish packaging option.

Why you should entrust the production of Attolis packaging

A reliable partner in the production of packaging solutions offers clients cooperation on favorable terms:

- personalized approach – individual offers for each customer, which allows you to take into account all the subtleties and think through the smallest details;

- high quality – strict adherence to technology, as well as mandatory control at each stage, which ensures compliance with specified standards;

- efficiency – branded packaging with logo will be produced on time and sent to the recipient for delivery without delay .

And to find out more about the order conditions and make a preliminary calculation, you just need to leave a request on the website – and managers will provide all the information of interest.