UV-varnish coating

UV-varnish coating adds extra aesthetic sheen to a printed product. The effect is achieved with the help of special varnish and the product gains additional visual attractiveness as a result. UV-varnishing increases the strength and durability of the printed product and makes it more attractive.

All products are made to order.

More examples

Hide

More examples

Hide

UV-varnish can be either glossy or matte, both of them have their advantages but both coatings are similar to lamination in respect to protection of printed products from staining and moisture. The varnish can cover the whole surface of a printed product or it can be applied only to specific elements (logo, picture, company’s name) to give accent to them. This is UV spot varnish.

To order printing and packaging with UV varnish from the company ATTOLIS, fill out feedback form , write to us in messengers or call: +380 (97) 790-90-00. Our company also provides post-printing and decoration services.

Complete varnishing of paper and cardboard products

This is an elegant way to give the surface a beautiful shine or noble matte finish. UV varnishing creates a protective barrier, minimizing the damage caused by moisture and dust. The liquid composition is applied to the entire area of the product: the rate of hardening when dried with ultraviolet light is minimal. An additional glossy coating makes the design brighter and more saturated, and a matte (Soft Touch) coating is pleasant to the touch and makes the appearance of the products more prestigious.

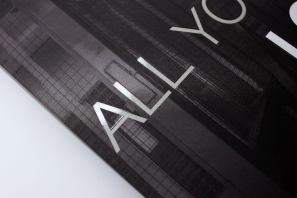

Selective varnishing

This is a post-printing process in which certain areas of a cardboard and paper product will be varnished to highlight details, create unusual visual effects and give the product a unique look.

Selective UV varnishing creates a contrast between matte and glossy surfaces, forming a beautiful pattern. This design attracts attention and accordingly stimulates consumer interest. And the variability of design will allow you to choose how to decorate cardboard or paper in accordance with the customer’s idea.

Additional effects

In addition to the classic continuous or selective transparent coating, you can use various non-standard design options:

- Volume varnish. Application of three-dimensional textures on surfaces using textured compounds, which creates a feeling of additional volume and relief. This technique is common in printing: applying UV varnish allows you to stimulate tactile interest in finished products.

- Glitter varnish. A beautiful shine with shimmering particles gives the product a bright, festive look. The degree of shine can be varied by combining different types of varnishes.

Glitter and volume – original ways to make a paper or cardboard base special, giving a basic design a new twist.

How UV varnishing occurs: popular types of varnishes

The composition is applied to the surface, covering it completely or highlighting certain areas. Special equipment will make possible impeccable precision, as well as strict adherence to the design concept. After application, the coating will be fixed by UV rays, which will provide the necessary hardness. Depending on the desired final result, offset or screen technology will be selected, which differ in density. Paper varnishing can be done with the following types of varnishes:

- matte;

- glossy;

- glitter.

Correct application will ensure uniform distribution of the composition without blisters and defects, which will simultaneously increase the durability of printing materials.

ATTOLIS benefits

We offer our customers a full range of services: from design development to its subsequent implementation. After agreeing on all conditions, specialists will begin work to ensure that the task is completed within the agreed time frame, regardless of the volume or complexity of the order.

In accordance with the design idea, a suitable UV varnish for printing will be selected, which will add strength and originality to business cards, brochures, and packaging for various categories of goods.

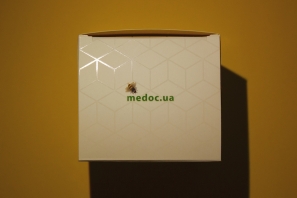

UV varnishing gives custom boxes to order a glossy or matte effect, enhancing their appearance and making them branded and attractive. UV varnishing is the process of applying a special UV-sensitive varnish to the surface of a product, which then dries and hardens under ultraviolet light, creating a high quality finish.

How can UV varnishing improve the appearance of custom boxes to order?

What is UV product varnishing and how does it work?