Hot stamping on paper and cardboard

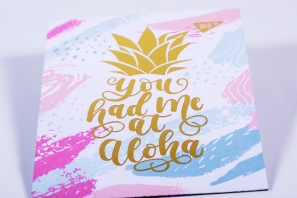

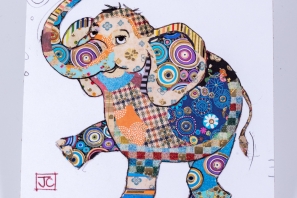

Hot stamping and foil stamping add elegance and refinement even to simple printed products such as business card or ordinary tag. By means of hot stamping technique a relief image is pressed into printed materials.

All products are made to order.

More examples

Hide

More examples

Hide

For this purpose, the product is placed between two closely fitted plates. The plates are tightly pressed against each other and as a result a relief image appears on the product (the image may be embossed or debossed). The rest of the printed product surface remains smooth.

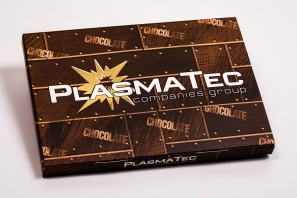

Hot stamping is frequently combined with foil stamping which enhances the relief effect of embossed elements and the packaging acquires decorated and distinctive look.

Hot stamping is one of the most interesting methods of post-printing finishing, as it allows for specific parts of printed products to be distinguished.

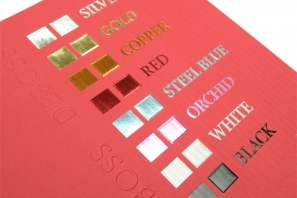

During foil stamping process foil is placed between a hot cliché with engraved elements and the product to be stamped and the cliché is pressed down. Owing to the high temperature of the cliché the foil pigment (metallic or color) is impressed into the surface of the product and sticks to it due to its adhesive components. These could be a company’s logo, name of goods or brand, trademark image or just additional decoration of a picture.

The price for congeal embossing depends on the volume of circulation, selected material, additional operations (lamination, hot stamping, etc.) the need for design development. The cold embossing method is used for smooth paper and fusible films. Dense paper, cardboard and leather are processed with a cliché heated to 60 degrees Celsius.

What is the price for foil stamping?

What materials can be embossed with congress embossing?