Lamination of paper and cardboard

To protect printed products from pollution (stains, grease) lamination technique is used - covering a printed product with transparent thin film.

There are the following types of lamination:

- glossy lamination is frequently used to add brightness and contrast while manufacturing visiting cards and advertising brochures;

- matte lamination allows to avoid glares and adds a low-key and velvety look to the product;

- Soft Touch - so velvet tactile coating.

All products are made to order.

More examples

Hide

More examples

Hide

Lamination and Soft Touch coating

Soft Touch is an increasingly popular matte coating that will make your printing look expensive and stylish. Printing with this coating is pleasant to the touch, while printed products are protected from wear and will last longer even with frequent use.

With Soft Touch coating, even business cards look different - more presentable, they are pleasant to hold in the hands of the recipient. For catalogs, brochures or menus of high-level establishments, Soft Touch coating is the best option.

Products on which lamination is used

One of the advantages of the popular post-printing method – versatility. Lamination is relevant for various categories of products:

- brochures, catalogues;

- business cards;

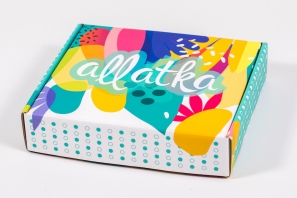

- packaging materials;

- postcards;

- menu in bars, cafes or restaurants;

- posters;

- advertising elements;

- discount cards.

The production capacity of ATTOLIS company has made it possible to quickly fulfill orders of large volumes; we cope with tasks of any complexity.

The difference between matte, glossy and Soft Touch lamination

Applying protective film to printing materials – an important production step that imparts aesthetic perfection and also increases service life. Lamination of cardboard or paper is available in various options:

- Matte – soft effect, without glare and reflections. The surface is smooth, pleasant to the touch, and does not slip in the hand. Ensures good text readability, especially on a dark background.

- Glossy – creates a shiny, reflective surface. Emphasizes the richness of shades, which enhances contrast. Due to its beautiful shine it gives the product a special luxury.

- Lamination Soft Touch (Soft Touch) – combines the advantages of both processing methods, which makes it possible to create a velvety surface with good resistance to scratches and prints. Enhances the richness of colors and gives shades a special depth.

The choice of coverage depends on your specific needs and goals. We think through the project in detail with each customer, coordinating every detail, which allows us to achieve an impeccable result that perfectly matches the task.

What materials can be laminated: density threshold

Modern equipment allows you to work with various categories of products, which has significantly expanded the capabilities of post-printing processing. Popular services:

- Paper lamination. This is the most common lamination material. The protective film can be applied to glossy or matte surfaces. Optimal density from 90 g/m² up to 350 g/m²: before starting work, managers agree on the choice of material based on the purpose, as well as the specifics of the further use of the product.

- Cardboard lamination. Medium or high density base is widely used in packaging and promotional materials. Cardboard density starts from 230-250 g/m².

The acceptable density threshold depends on the equipment used. Paper that is too thin or very light materials may warp during the process, while materials that are too thick or dense are more difficult to process in the laminator and require more powerful equipment.

Tips when choosing lamination

Managers will offer up-to-date solutions in accordance with the result the customer wants to receive. Therefore, it is necessary to: voice the idea, and also familiarize yourself with the presented samples. This will allow you to choose the current type of coating – and printing with lamination will be done according to the approved layout.

Lamination of paper and cardboard is necessary to protect printed products from dirt and wear.

What is the purpose of laminating paper and cardboard?

Types of lamination