We needed boxes for VIP gifts: champagne and delicacies. It wasn’t just about printing, but a full structure with dividers and windows. The team even included an assembly guide — brilliant! Our partners sent glowing feedback, the presentation was top-tier.

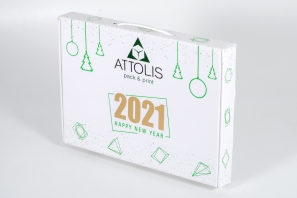

Christmas boxes

ATTOLIS is a professional producer of paper, cardboard and corrugated board packaging. Various goods are packed in cardboard packaging of our production - jewelry, food products, candies, textiles, utensils, technical devices.

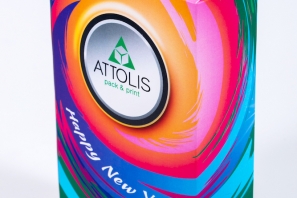

We produce both large-volume packaging for New Year's sweets and individually designed medium-volume packaging for New Year's gifts.

Our production facilities and experience of more than 20 years allow us to develop and manufacture individual packaging for goods, including decorative packaging, using various printing and processing techniques.

For the production of branded New Year's packaging we use cardboard, laminated micro-corrugated cardboard, durable corrugated cardboard and exclusive designer cardboard - all according to the wishes and ideas of customers.

At ATTOLIS you can order your branded New Year's packaging:

- packaging is produced in small, medium and large editions;

- the development of the design of the package is based on the parameters of the content that will be inserted in it;

- packaging is made individually for your New Year's gifts or we may offer worked out packaging designs with sizes and shapes that match the dimensions of the contents;

- we produce branded packaging, packaging can be branded with a logo or fully decorated in the corporate design of the customer company;

- in addition to packaging, you can order at ATTOLIS printing with various processing techniques - applying hot stamping and foil stamping, applying selective or continuous UV varnish, branding of thin wrapping tissue paper, branding of satin and corded silk ribbons.

Our customers of corporate New Year's packaging often complete their gifts with postcards made of ordinary coated cardboard with print or designer cardboard with embossing; branded notebooks; corporate quarterly calendars; branded boxes for sweets from ATTOLIS.

All products are made to order.

More examples

Hide

More examples

Hide

Packaging for corporate New Year gifts

Every year before the New Year holidays, companies prepare their corporate gifts, which they give to customers, partners and employees on the New Year's Eve. The choice of gifts is limited only by imagination.

A standard corporate gift set consists of:

- Calendar for the next year;

- Notebooks and diaries;

- Boxes of chocolates or other sweets;

- Sparkling wine bottles;

- Any useful things can be a New Year's corporate gift: a plaid, an umbrella, a cup or a mug.

All variants of corporate gifts have one important element in common - the presence of a logo on them. Notepads, pens, cups, and plaids are branded with the company logo. In addition to positive emotions of the recipient, the company that gives gifts receives effective advertising.

ATTOLIS will produce high-quality branded packaging for corporate New Year gifts. The packaging is made taking into account the dimensions and weight of the contents, a logo can be printed on the box, or the whole box can be decorated in an individual design of the company.

in packaging creation

service

Satisfied customers

production

New Year's packaging material and decoration methods

ATTOLIS produces packaging of any complexity, has many years of experience and professional production equipment. We produce various options for cardboard packaging:

Digital printing ATTOLIS offers digital full color printing for branding cardboard boxes for honey jars, sweets, cosmetics, soaps and other products of suitable size. We produce such packaging in small and medium runs. Pros: Silk-screen printing Today the technology is widely used in the printing industry. ATTOLIS company performs silk-screen printing on paper, cardboard, corrugated board, plastic and other materials. Features You can create an image using one color or several different colors, you can make a metallized or fluorescent image. For each color, its own stencil grid is created, the cost of silk-screen printing depends on the number of printing colors. Offset printing Today this technology is widely used in printing houses. ATTOLIS offers qualitative offset printing on boxes and packaging. Our experts will impliment any ideas of the client, make an unusual design for an individual order. We use offset printing to produce full color, durable corrugated boxes. Printing is not applied directly to corrugated cardboard, but to cardboard sheets. We use the laminating method on our special equipment - we glue cardboard with full-color offset printing to corrugated cardboard, cut it to shape, fold ready-made durable colorful boxes. Features Pros: Embossing ATTOLIS has all the necessary equipment for foil stamping and hot stamping, which allows us to implement different customer ideas in packaging decoration. When processing foil stamping, a foil is laid and pressed between the metal plate and the material, a metallized imprint remains on the material. For stamping we can use foil: Dyed embossing, i.e. embossing on print, is often used for the production of branded packaging. Additionally, selective UV varnish can be used, then the print will be even more voluminous. Features For one relief print 2 cliches are needed, which will compress the material from the front and back sides. The demand for this type of printing services is constantly growing in the field of business and advertising. Often in the manufacture of packaging and printing, printing is not used at all, all images and texts are applied by hot stamping and foil stamping. In addition to relief stamping and foil stamping, we also perform Silk Foil stamping without clichés. Silk Foil allows us to get an eminent image in the color of bronze, gold, silver, which is not depressed on the back. UV Coating In case of packaging branding by application of spot UV coating, the logo is applied with a transparent ultraviolet material, which makes it possible to highlight the brand name, gives it an overflow effect, but does not make it too catchy. To obtain a more colorful image, the logo can be printed by offset or digital printing with further UV varnish coating. An embossed, tactilely perceptible picture is provided by applying a "high" UV varnish. UV varnish can highlight not only the logo, but also other elements: illustrations, lines, company name. Adding glitter to the varnish allows to obtain a glitter material that will provide shine and attractiveness to the packaging design elements. Features Also UV-varnish can be matte - Soft Touch coating gives velvetiness to surface of printed products. The application of a special varnish provides: The use of UV varnish allows to create truly exclusive products.

Digital printing - transferring an image onto cardboard or paper using a laser, inkjet printer or printing machine. Application of paint directly to the sheet does not require longtime and expensive preparation. It is the ideal solution when for producing small runs of compact packaging boxes under tight deadlines.

Minuses:

Silk screen printing is a modern type of screen printing, which is performed using a special mesh. The thick paint under the pressure of the squeegee hits the surface through the holes of the mesh, on which the stencil of the future image is created. The print is dried with hot air and special lamps.

The screen-printing method is used for branding the packaging, applying prints, text, illustrations. This method allows you to obtain clear, high-quality printing keeping the original color of the image at the background of any color. So the brand logo printed on the cardboard packaging will remain in the corporate color, no matter what shade the background of the packaging is. Silk screen allows you to apply matte, glossy, complete or spot UV varnish.

Offset printing is a technology that involves applying an image to paper or cardboard by transferring it through special rollers. This method requires significant time and money, but the image quality is high.

Offset printing guarantees accurate color reproduction, contrasts and smooth color transitions.

Minuses:

Embossing is a creation of a sculptured image on a printed material by compressing it between cliches. Cliches for embossing are made according to the layout, in cliches the necessary shapes are cut out, they will leave an impress on paper or cardboard. The relief of the image can be eminent on the front side (embossing), or depressed (debossing).

For embossing, it is necessary to order the production of metal forms (cliches), their cost is calculated depending on the area of the embossed elements.

UV coating technology gives printed products a gloss and matte finish without lamination. Matte or glossy varnish can be applied to the entire surface of the product or selectively to make certain elements more noticeable.

Ultraviolet varnish has a high gloss, dries quickly, and is resistant to chemical and physical stress.

- Cardboard boxes. Any full color print can be applied to coated or recycled cardboard. The outside surface of the carton can be coated with glossy, matte lamination or UV varnish.

- Corrugated cardboard boxes. Corrugated cardboard is a durable material that has high shock-absorbing properties and is able to protect goods from damage. We produce corrugated cardboard boxes of various thicknesses.

- Laminated boxes. Nowadays, a very popular packaging type, as laminated packaging is both durable and colorful. To manufacture durable packaging, decorated in a corporate design, we use the lamination method - gluing a sheet of printed cardboard to a sheet of corrugated cardboard. Boxes for heavy items can be equipped with plastic handles for easy transport.

For branding and printing on packaging, we use various methods - digital and offset printing, hot stamping and foil stamping, selective and continuous UV varnish, silk-screen printing, which allows to save the original shade of the logo on any even brown cardboard, and any colors can be metallic. We also apply glitter varnish to packaging and printing - coating with sparkles, their use is especially important for festive products.

How to order a calculation of the cost of customized packaging in ATTOLIS

for product creation

- Decide on the contents of the box. In order to choose the right packaging option, it is important to know the size and weight of the contents in advance.

- You can find examples of designs that you like.

- Pre-estimate how many items of packaging you need, since the cost of one box depends on its size. With an increase in circulation, the cost of one unit can be significantly reduced.

- Send us an application with all the available data, you can use the feedback form on the site, send a message by e-mail or messengers, or call the phone number.

- The manager will contact you to clarify all the details of the order and provide a calculation for the production of packaging.

A ready-made packaging layout can be provided by the customer, or ATTOLIS specialists will help to develop it. The development of the layout is carried out under condition of placing an order for the circulation of packaging in ATTOLIS. The cost of developing a layout is determined after receiving a technical assignment for a design from a customer.

Order packaging from Attolis

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |

Client Reviews

We aimed to create a winter fairytale for a limited honey with mint edition. The complex design with silver foil on dark blue made us worry, but the result looked like a magazine cover. Only downside — due to demand we waited 3 weeks, but it was worth it.

For our New Year candy assortment we needed a unique package. ATTOLIS created an option shaped like a Christmas ornament. Print is crisp, colors rich. We'll return again for the truffle collection for Women's Day!

ATTOLIS has no maximum print size limit. We have installed professional equipment that allows us to carry out all production processes - printing, post-printing, die-cutting, gluing - at the optimum time. We produce regular large editions. Yes. In the production of any type of custom-made cardboard packaging, the rule applies - the more circulation you order, the less the cost of a packaging unit will be. Yes. We will develop a packaging design for your product, make a trial sample so that you can make sure that the design is working and that the size of the package matches the size of your product. The cost of manufacturing a test sample is calculated individually and depends on its size, design and materials used. ATTOLIS produces bespoke customized packaging. Minimal quantity of small sized cardboard packaging - 300 pcs. Minimal quantity of middle and large sized cardboard and corrugated board packaging - 500 pcs. You can order cardboard packaging on the company's website. Qualified specialists will help to prepare the layout and select the design of the cardboard packaging in accordance with the preferences of the customer. Depending on the design, the packaging can be sent to customers assembled or disassembled. For example, self-assembled boxes are shipped by default to the customer unassembled and are folded by the customer manually without glue. This is a convenient option, since even a large circulation of such boxes does not take up much space during storage. If you have no experience in folding such boxes, we will gladly send you a video instruction. We work exclusively with high-quality materials and only with official suppliers of materials - cardboard, paper, paints, varnishes. Paper and cardboard allow you to keep the freshness of food for a long time without compromising the taste. When interacting with food, cardboard food packaging does not emit toxic substances that can be harmful to human health or the environment. Yes of course. We will check your packaging or printing layout for technological correctness, but we are not responsible for low-resolution pictures, text content, loose fonts and typos in the layout you provided. We can warn you about low resolution images or lack of proper margins in your layout. At your request, we can modify and correct your layout.

What is the maximum circulation of packaging for an order?

Does the cost of ordering packaging depend on its circulation?

Is it possible to get a trial sample of packaging before ordering a print run?

How much does it cost to make a trial sample?

What is the minimum circulation of packaging for an order?

Will I receive ready assembled boxes?

If you want to receive your boxes fully assembled - check this point with our manager.

What materials do you use to produce food packaging?

I have a ready-made layout, will you check it before printing?