Folding

All products are made to order.

More examples

Hide

More examples

Hide

During folding process several folds (up to 8 if necessary) are formed on a printed sheet in a sequential order.

Usually folding is performed on special equipment with rollers (a folding machine) where the printed sheet passes between pressure rollers. Folding is necessary to reduce or avoid cracking and breaking of printed products with high density (from 170 g/m2 and more).

Folding is usually preceded by creasing procedure to make folding lines more accurate and thin. Then no wrinkles appear along the folds of the bended sheet, and as a result there will be no harm caused to quality.

Scope of application of folding

The process of bending material along predetermined lines is relevant in the production of various categories of printed products. There are several key areas in which folding is relevant:

- all types of boxes and other designs for packaging goods;

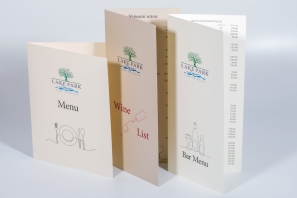

- printed materials, including brochures, eurobooklets;

- advertising products, flyers, postcards;

- office – notepads, calendars.

This service is relevant for many industries, which makes it an important link in the production of packaging and printing products.

What determines the quality of folding?

There are certain standards and criteria that allow you to evaluate finished products. The following factors influence the result:

- correct placement of pages in a given order;

- accuracy of fold placement;

- clear every fold;

- high density of joints, which is ensured by high-quality glue.

Defects or minor damage that affect the appearance and, most importantly, the functionality of the materials are unacceptable. Multi-stage quality control has been implemented in production, and the use of modern technologies and automated systems allows us to minimize the appearance of defects or “wrinkles.”

Folding in printing: types

Depending on the specifics of working on the task at hand, as well as the characteristics of its implementation, the following types of folds can be distinguished:

- Perpendicular – for making rectangular or square shapes such as boxes, postcards. Provides crisp corners and smooth edges.

- Parallel – for long or narrow shapes. Uniform, smooth folds are relevant if you need to fold instructions, brochures, booklets or other compact products designed to contain information.

- Combined – combining different fold options to create complex shapes.

Each of the options has certain advantages, and the choice depends on the approved layout. The number of folds plays an important role: maximum – 4, the most common format – 3-4.

Folding methods

The correct folding of a paper or cardboard base directly depends on the quality of the folds. Folding in printing can be done using the following methods:

- knife – universal, economical;

- cassette – accurate, fast.

For processing large batches, it is optimal to use the cassette method, and for small batches, the knife method is suitable. But each request will be considered separately so that the binding activities are carried out in accordance with the customer's requirements. For example, when working with drawings, the folding can be made with or without a spine – depending on the specifics of further use of the product.

ATTOLIS benefits

Our team will make sure that folding paper or cardboard is done quickly and accurately. Conscientious craftsmen will carefully prepare the foundation for work, set up automatic equipment, and also promptly carry out all the necessary manipulations. After completion of the production cycle, the materials will be quickly packaged and sent for shipment.

Folding can be used to create the complex shapes and folds required for custom boxes to order. It allows you to precisely fold and crease the material to create a customized box design. Folding allows you to create look and function without the need for manual assembly. It facilitates production, reduces time spent and ensures quality results.

How can folding be used to create custom boxes to order?

What are the benefits of folding for printers and print manufacturers?