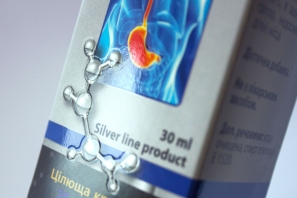

Medical Device Packaging

The main concept of ATTOLIS is to create reliable products.

The manufacture of packaging for medical products is carried out from high-quality materials obtained from reliable reliable suppliers:

- Laminated corrugated board – obtained by gluing together sheets of ordinary cardboard and corrugated cardboard. This type of cardboard is used for the production of durable branded boxes.

- Coated cardboard – convenient for full-color printing on pill boxes, can be of any density.

- Microcorrugated – durable material that preserves the integrity of medicines in vials, suitable for mailing goods.

- Craft cardboard – durable material, available in two colors standard brown or bleached. Using the silk screen printing method, it is possible to apply a logo in the original corporate color even on brown craft.

All products are made to order.

More examples

Hide

More examples

Hide

Cardboard packaging and printing for pharmacies and medical institutions

ATTOLIS manufactures custom-made branded cardboard packaging using modern powerful equipment: printing equipment, both full-color and silk-screen in one or several colors, die-cutting equipment, folder-gluing machines, laminating equipment, equipment for applying solid and selective UV varnish, machine tools for embossing and foil stamping.

For medical products, ATTOLIS manufactures the following types of products:

- Boxes made of coated or recycled cardboard. A lot of goods are packed in such boxes - tablet preparations, bottles, medical accessories (medical masks, pillboxes, patches and much more). This is the most common type of packaging.

- Boxes made of durable corrugated cardboard and corrugated cardboard laminated with a sheet with full color printing. This is a reliable and durable packaging option for fragile, high-value or bulky goods.

- Package with additional separator insert. When packing, for example, several bottles in one box, in addition to the box, a cardboard insert is made according to the size of the products, it will prevent the bottles from touching each other in the box and preserve their integrity.

- Show boxes for displaying goods in a showcase. These show boxes are mainly made of laminated corrugated cardboard, using the laminating method (gluing a sheet of cardboard with color printing to a sheet of corrugated cardboard), ATTOLIS produces strong and colorful show boxes that attract the attention of customers and securely fix the goods inside.

- Printing: advertising booklets and brochures, black and white folded instructions for inserting into product packaging, branded packaging for client and gift cards.

What requirements should a carton package for medicines meet

Cardboard is used to create two types of packaging material:

- Secondary – designed to contain all data identifying medicinal products.

- Group – used for convenient transportation of a group of medical products that are placed in secondary packaging.

A certain range of requirements is imposed on secondary pharmaceutical packaging:

- Boxes for medical products should be airtight and provide protection from light and moisture.

- Volatile substances and odorous medicines should not be stored together.

- All types of liquid and volatile formulations are placed in glass or plastic containers and then placed in a secondary carton.

- Ampoules, vials, bottles are laid out in a cardboard tray, and then in a box.

- According to the laws of Ukraine, packaging containers must contain information about the drug in Braille.

If all approved standards are observed, the packaging for medicinal products retains the physical and chemical properties and activity of the medicinal product until the end of the expiration date.

What information should be placed on the package

The box for pills and other primary products must contain the following information:

- trade name of the drug;

- dosage, concentration;

- trademark of the owner or manufacturer;

- batch number, series;

- Expiration date.

Packaging for secondary type tablets requires the placement of more detailed information that allows for convenient logistics and accounting. It additionally indicates:

- date of production;

- storage conditions, order of issue;

- method of application;

- barcode, if any;

- precautions, if any;

- medication composition.

Production of packaging for medical products by ATTOLIS

The company can order digital and offset printing, silk-screen printing, embossing or UV varnishing. Each method has its own advantages, the choice depends on the characteristics of the order and the type of product to be packaged. Packing is made individually under the order - by the sizes of goods. ATTOLIS also provides post-print processing and drug box decoration services:

- cutting windows in the package with subsequent gluing of transparent plastic or without;

- foil stamping - matte, glossy, holographic;

- numbering/personalization - applying variable data to packaging or printing;

- solid or spot UV varnish application

- applying glitter polish;

- folding booklets and instructions;

- 3D embossing

Order packaging from Attolis

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |

How to order packaging for medical products in ATTOLIS

You can order the production of boxes from ATTOLIS according to a standard or individual project. Main stages of the order:

- Formation of order details indicating the future contents of the box. In this way, it will be possible to develop the most suitable package design option.

- Developing a layout and a test sample for a product.

- Approval of the layout, coordination of cost and terms.

- Starting production.

ATTOLIS has many years of experience in creating quality packaging materials. Thanks to the full production cycle, it is possible to create cardboard boxes of any complexity in regular runs.

The cost of printing medical boxes will depend on the size of the product, the number of post-printing operations, the circulation and the selected material for production. Among ATTOLIS customers the most in demand are boxes for medical masks, packaging for medical equipment, show boxes for food additives.

How much does it cost to make cardboard boxes for medical products?

Which medical device boxes are the most in demand?