Creasing paper and cardboard

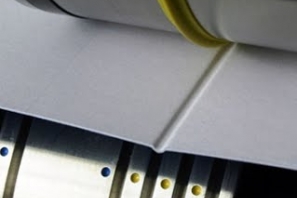

Creasing is one of post-printing processes when a special path is created on paper or cardboard along the entire length of a desired fold with the help of blunt rotary wheels. The dented path prepares material for bending/folding and makes it easier, especially when this operation is applied to products made from heavy stock paper (with density of 170 g/m2 and more).

All products are made to order.

More examples

Hide

More examples

Hide

Creasing ensures accurate folding without cracking or breaking even for thick cardboard.

The method of creasing has a number of significant benefits:

- the printed product easily takes necessary shape;

- increase of material endurance in the folding points;

- even printed cardboard has no cracking along the folds;

- no cracking or splitting of layers occur in a printed product when bent or folded.

What printed products are creasing used for?

Modern automated scoring equipment has made it possible to work with various categories of materials:

- Cardboard. Cardboard creasing is relevant for creating packaging, postcards, book covers or other products where rigidity and strength of external elements are required for reliable protection of goods.

- Thick paper. Use for brochures, booklets, and cards that require clear folding areas.

- Film. Allows the formation of folds and recessed areas, which is convenient for the production of covers, as well as transparent packaging.

This service is always in demand and is suitable for working with various materials, including plastic.

Creating technology

To bend cardboard or any other base, you must complete the following steps:

- prepare a project – determine the location and shape of deepened lines or grooves;

- make a scoring stamp with appropriate scoring knives, taking into account the density of the material and other parameters;

- perform creasing – The scoring die creates recessed lines on the surface of the material, following the contour defined in the design.

This technology – an important stage in the production of various types of printed products and packaging, which increases the functionality and attractiveness of the finished product for customers.

Equipment for creasing in a printing house

In rare cases, in particular when the fibers of the material are perpendicular to the fold line, a manual method is used. But most projects use automated machines that create furrows using impacts. The impact head passes through the material and forms strips of the desired depth. Suitable for dense and thick substrates, and also provides high processing speed for large batches.

Experienced specialists will ensure that creasing is completed as quickly and efficiently as possible.

Difference between creasing and folding

These are two finishing processes that successfully complement each other:

- creating grooves, grooves or other types of depressions – creasing;

- folding printed materials in a given sequence – folding.

The ATTOLIS company offers customers a wide range of services, as well as favorable prices for the production of printed products. Our team will make sure that paper creasing is completed on time and in full accordance with the approved project.

The technological operation of creasing is performed on cardboard, heavy paper, film, plastic. This type of postpress processing is used for the production of boxes, leaflets, brochures, book and magazine covers, and branded bags.

What materials are creasing for?

Where is creasing used?