Cutting-off

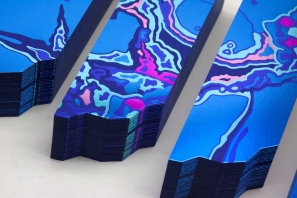

Cutting-off technique is necessary to use to cut a printed sheet in parts when, for example, several items are printed on one sheet.

By the cutting-off method necessary shape and exact size of printed products are achieved.

All products are made to order.

More examples

Hide

More examples

Hide

Cutting-off allows to cut away all unprinted areas on each side of a printed sheet (white edges). This is connected with peculiarities of printing equipment which has some limitations for any type of printing. During cutting-off process two perfectly straight perpendicular sides are obtained and all further operations will be done with regard to those sides.

Features of cutting paper and cardboard

In the production of packaging or advertising materials, cutting cardboard and paper – an important part of most projects. The quality and accuracy of edge processing is influenced by the choice of tools and equipment, as well as the preliminary preparation of the material.

The thinner the base, the more careful handling it requires. And for dense products, increased power will be required. The standard cutting angle is 90 degrees, which is necessary to obtain crisp, neat edges.

Types of cutting: guillotine, plotter cutting, cutting with tall knives

In the production of printing and cardboard and paper packaging, the following cutting methods are used:

- Guillotine cutting. The process is carried out on special cutters; on an industrial scale, electro-mechanical cutters are used, which have a large cutting length and power, due to which the machine operator can cut a large number of sheets with one cut, but guillotine cutting can only produce an even cut, not a figured one.

- Plotter cutting. This method can be used to cut elements of any shape. In addition, the plotter can be used to make cuts on self-adhesive materials, for example, when making sticker packs - the plotter does not cut through, but cuts only the top layer, and we get a set of stickers on one sheet. The disadvantage of this method is speed - the plotter knife cuts each element separately, so this cutting method is suitable for small runs and not suitable for large ones.

- Cutting with nibblers. This method uses a die-cutting stamp - a sheet of plywood with knives inserted into it along the contour of the future product. This is a necessary stage in the production of large runs of packaging and printing of non-standard shapes.

The choice between existing cutting methods depends on the specific requirements of the project, as well as the characteristics of the material. Specialists will select current solutions in accordance with the customer’s request, combining cutting quality, efficiency, and speed.

Scope of application

Packaging performs several important functions at once: protecting goods, promoting them, and most importantly increasing brand awareness. To produce cardboard boxes of the desired shape, correct cutting with high precision of parts is important.

Cutting is relevant in the production of printing and souvenir products. At the initial stage, a layout will be created, on the basis of which a processing method corresponding to the characteristics of the material will be selected.

ATTOLIS benefits

We use multifunctional modern equipment in our work, which has allowed us to speed up basic processes through automation. This significantly reduces the time spent on order fulfillment: cardboard cutting will be done accurately, efficiently, and quickly. In addition to efficiency, other advantages are available:

- loyal pricing policy;

- responsible, conscientious work;

- personalized approach.

Customers can use individual services or order a full cycle: from layout to production of the finished product.

Additional operations

Production facilities allow us to offer customers a wide range of post-printing processing options, including:

- lamination;

- foiling;

- UV varnishing;

- folding;

- folding;

- 3D embossing.

Managers will answer all your questions in detail, select a profitable format for cooperation, and calculate the cost. Cutting paper or cardboard, as well as related operations, will be performed flawlessly and on time.

Cutting is used to cut and shape custom box to order parts from raw materials, usually paper or cardboard. It allows you to create products of different shapes and sizes. Various cutting methods such as laser cutting, dielectric cutting, water jet cutting and traditional mechanical cutting are used in production.

How can cutting be utilized in the custom box to order making process?

What cutting methods are used in manufacturing?