11.05.2021

Beautiful packaging turns dessert into an exquisite gift – This is a universal souvenir that is guaranteed to please the recipient. The ATTOLIS company offers customers the production of boxes for chocolates of any size. High-quality packaging made from environmentally friendly materials is safe for contact with food, and most importantly, it is complemented by stylish design.

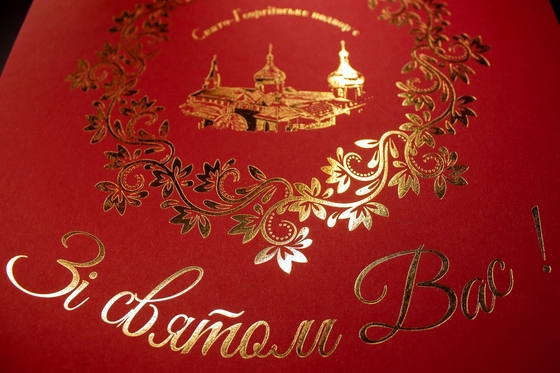

Festive boxes for sweets produced by ATTOLIS.

The boxes are made of deep red premium cardboard, which is harmoniously combined with the image applied with embossed gold foil.

Stages of making boxes for sweets

The process begins with design development. Specialists are working to create functional, attractive products so that packaging for confectionery looks expensive and solid. The design will take into account the specifics of the future content, its volume, as well as other characteristics. After approval of the project, the ATTOLIS team will begin production, which includes a number of stages:

- choice of materials – sheets of cardboard of various densities are available, which will allow you to find the optimal ratio of thickness and strength;

- print – equipment is used for offset and digital printing, as well as silk-screen printing;

- applying decor – production of boxes for candies includes post-printing processing;

- cutting, gluing – After applying images or inscriptions, the materials will be cut along the specified contour to give the product the desired shape.

Final stage – assembly followed by packaging. Liners, internal compartments or other relevant details will be added as needed.

Decorating candy boxes

Each stage of production plays its role in creating attractive and, most importantly, functional packaging. Candy box printing includes additional decoration using the following methods:

- Embossing – creating relief drawings or voluminous text on the surface. This gives expressiveness and increases the visual appeal of the product for potential buyers.

- UV varnishing – applying a special coating that hardens when exposed to ultraviolet rays. The outer part of the packaging can become either matte or glossy; a combination of elements is also possible. Making a candy box with a dense protective coating increases its strength, protecting it from moisture and damage.

- Volume embossing Silk Foil – foil coating with high heat resistance gives the products a special luxury.

- Applying glitter varnish – bright, shiny details give a feeling of celebration. Using varnish, you can highlight the entire image or individual parts of the picture, decorate the text or make an interesting border.

By entrusting the production of candy packaging to professionals, the customer receives a full cycle of services: from design development to final post-printing processing. The company produces candy boxes in small and large quantities: finished products will be promptly sent to the recipient.

Order packaging from ATTOLIS

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |