To obtain a thinner, but at the same time strong and even base, convenient for high-quality printing and presentation of goods, a special material was created, which became a good alternative to standard packaging solutions. What is micro-corrugated cardboard? This is a type of corrugated cardboard with a very thin profile - up to 1.8 mm, which is characterized by increased resistance to end loads. ATTOLIS produces durable, effective and environmentally friendly boxes and inserts using lamination technology - applying a printed layer to the outer or both sides of the box. Thanks to this approach, designer packaging is created, which is easy to adapt to the style and objectives of the brand.

Microcorrugated cardboard: what is it and why is it needed

Among the advantages of this material, it is worth noting the optimal ratio of weight and rigidity, which ensures reliable protection of goods during transportation. The smooth front surface makes it possible to apply any inscriptions or images, including using various methods of post-printing processing. Many brands prefer this type of packaging materials for the following reasons:

- small overall profile;

- good rigidity with low weight;

- reliable protection of contents from mechanical damage.

There are quite a few types of corrugated cardboard: letter designations are used to classify profiles. A is a corrugation with a thickness of up to 9.5 mm, which provides good cushioning. C is a common and universal option. Microcorrugation has received the E mark and is intended for small but strong boxes of complex shapes and designer packaging.

Advantages of micro corrugated cardboard why choose it

Among the practical advantages that directly affect logistics, cost and the end customer's perception of the brand:

- saving space in transport;

- presentable appearance;

- flexibility of design.

These advantages of micro corrugated cardboard have determined its popularity. And in comparison with thick corrugated cardboard or wooden inserts, the material is often more economical for small and medium-weight goods.

Where is micro-corrugated paper used in packaging

This is a great option for all areas where a balance between presentation and protection is needed. It is not intended for heavy loads, but works great in retail and e-commerce, where premium packaging is used, the appearance of which is as important as functionality. Where micro corrugated cardboard is used:

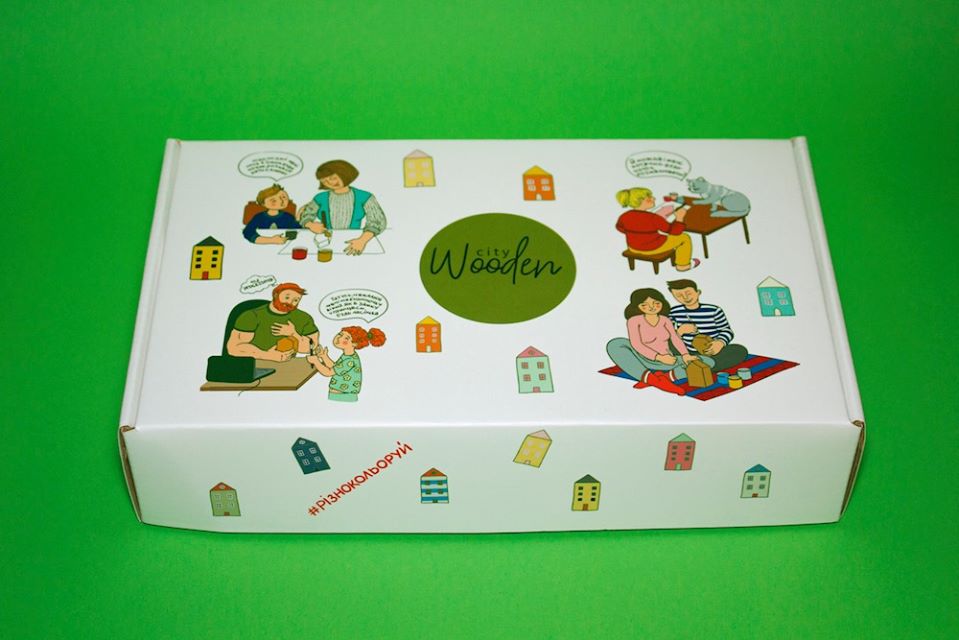

- compact gift and branded boxes to order;

- packaging for electronics, accessories, confectionery, perfumes, cosmetics;

- slots, inserts and lodgements;

- rigid mailing envelopes for catalogs, certificates, samples.

For businesses, this format means reduced logistics costs and increased brand perception due to attractive packaging without excess weight.

Microcorrugation and ecology

The material fits well into environmental strategies: it can be made using secondary raw materials and is recyclable. And such packaging for cosmetics, as well as other categories of eco-products and products with a natural composition, will be favorably received by the end consumer.

Order a box from ATTOLIS

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |