Boxes have long ceased to be just a shell — they are a full-fledged tool for sales, communication, and brand positioning. By considering the packaging trends of 2026, it is possible to create functional and stylish packaging that positively impacts customer loyalty and repeat purchases.

Eco-Friendly and Sustainable Materials

Conscious consumption is becoming one of the basic standards. Customers evaluate packaging characteristics, the possibility of reuse, and its environmental impact. Priority approaches include:

- recyclable materials — cardboard packaging complies with international environmental standards and suits various product categories;

- plastic reduction — cardboard inserts or molded paper structures are used instead of plastic components;

- biodegradable coatings and inks — water-based and eco-friendly inks maintain print vibrancy without harming the environment.

Volume optimization is also important: reducing empty space inside the box lowers material usage and logistics costs. Modern packaging design should be clean and subtle, reinforcing the natural character and aesthetic of the product inside.

Interactive Packaging Elements

Functionality has become a core attribute. Integrating digital elements into packaging design increases engagement and extends interaction with the product. Popular solutions include:

- QR codes — linking to instructions, video reviews, loyalty programs, or exclusive content;

- AR effects (augmented reality) — when scanned with a smartphone, interactive packaging “comes to life” with animations, 3D product models, or brand greetings;

- hidden internal elements — additional messages, creative visual effects, and gamification features.

Such details can be applied to standard packaging or designer cardboard boxes. For the premium segment, personalized packaging is available: each batch can feature a unique code leading to a dedicated promotional or special offer page.

Personalization and Small Batches

In 2026, demand for small runs and customized solutions continues to grow. This is particularly relevant for:

- launching a new collection;

- limited-edition releases;

- corporate events.

This approach is also suitable for seasonal and holiday editions. Limited production increases perceived value and encourages repeat purchases, fostering long-term loyalty.

New Visual Trends in Printing

Technology is combined with tactile expressiveness. Brands actively use techniques that enhance premium perception and shelf recognition:

- metallic elements and foil stamping — emphasize depth, shine, and visual impact;

- textured effects — both standard and laminated boxes often feature embossing varnish, soft-touch coating, or textured cardboard;

- minimalism and bold typography — clean backgrounds, strong brand name focus, and reduced visual clutter.

Packaging and printing go hand in hand: trends demand creative solutions that help brands stand out in a competitive market while reinforcing quality perception.

Printing Technologies That Accelerate Production

Digital printing enables fast production of large batches without lengthy plate preparation. Thanks to automated post-press processes, cutting, creasing, and gluing are performed with high precision and minimal manual involvement. Quality control systems eliminate defects during production.

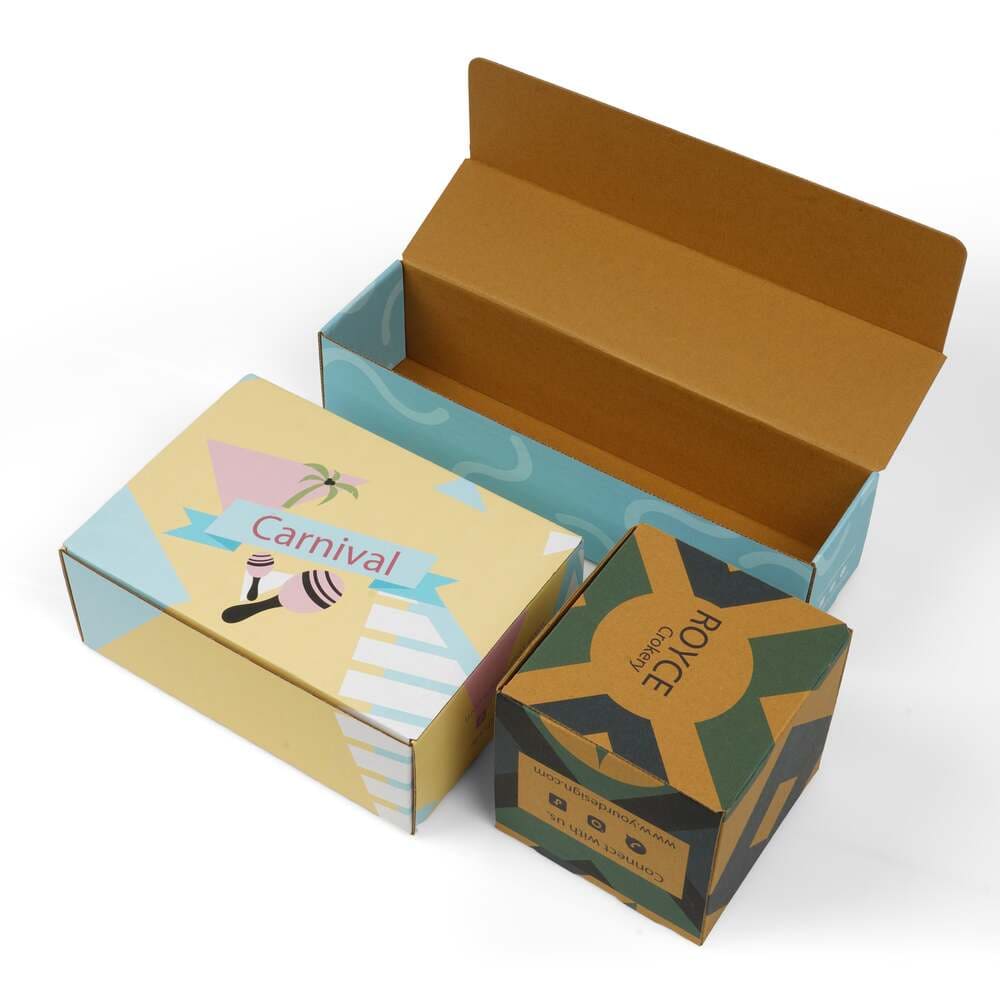

Examples of Implementing Trends in ATTOLIS Packaging

The combination of sustainability, advanced technology, and expressive design is always a winning solution. Implementation options include:

- using recyclable materials for shipping and gift boxes;

- integrating interactive elements;

- producing limited editions.

The ATTOLIS team monitors packaging printing innovations, offering clients practical and visually impactful solutions that support both brand image and sales. Whether gift boxes, packaging for fragile or heavy goods, or confectionery packaging are required, an optimal solution will be provided.

Order a box from ATTOLIS

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |

Special offer from ATTOLIS

Modern production equipment allows us to offer customers the widest range of services available. Experienced managers will select the optimal design options for packaging materials depending on the specifics of the goods and the positioning of the business. After agreeing on the terms of the project, a preliminary calculation will be performed. And to save money, it is profitable to order gift boxes with embossing in bulk – and large quantities will be promptly manufactured and delivered to the recipient.