Boxes made of kraft cardboard

Kraft boxes, eco-friendliness and durability

Kraft boxes are practical products, fashionable direction in the modern packaging market. They differ in their simplicity, originality and relatively low cost. Solid boxes are suitable for packaging gifts and any goods, from food to household appliances.

ATTOLIS is a well-known company that has been manufacturing various types of cardboard packaging since 2000. Here you can order branded kraft boxes of a suitable size and print a logo on them or any prints, or slogan. We accept orders for the manufacture of original kraft products according to individual parameters.

The material of manufacture

For the production of kraft boxes, plain or corrugated cardboard is used. Kraft material is obtained by various types of pressing. One of its advantages is its lightness with high strength, in addition, you can note the following advantages of trend kraft:

- Versatility. Cardboard is used for the production of any type of packaging.

- Environmental friendliness. The material is made from natural raw materials: waste paper, wood, cellulose, so it is completely safe for both use and disposal.

- Reliability. Corrugated cardboard with a kraft liner is resistant to mechanical damage, has high anti shock properties. A corrugated sheet, i.e., a wavy sheet, can withstand loads that are too much for a flat sheet. At the same time, the flat layer prevents deformation of the "corrugation” and helps it maintain its rigidity.

- Resistance to external influences. Laminated from the inside craft boxes do not pass moisture.

The material has an attractive appearance, mainly kraft is brown, but can be white inside. Strong boxes made of micro corrugated cardboard with a brown cellulose layer - this is a beautiful and reliable packaging, the outside of the box will be of a rich brown color.

All products are made to order.

More examples

Hide

More examples

Hide

Advantages of kraft boxes

Kraft boxes have a number of advantages that ensure their wide popularity:

- environmental friendliness;

- strength;

- ATTOLIS has developed methods for applying high-quality images to craft packaging;

- branded boxes are an effective advertising tool.

If you don't know where to order branded kraft boxes, you may contact us. We guarantee high quality of our packaging and ensure your brand awareness.

Our production is a place where brands can order their customized packaging

Founded in 2000, ATTOLIS was originally engaged in the production of packaging from cardboard and corrugated cardboard.

The company's machine fleet has been updated since 2009, together with the improvement of packaging production, the company develops printing and post-printing processing.

From 2012 to 2016, experience was actively gained, new lines were installed, including the production of envelopes, powerful die-cutting machines, folding and folding-gluing equipment were installed. The equipment fleet has been expanded with machines for applying personalization to printed products - barcodes, addresses, individual numbers, and personal appeals.

Today our production site has modern high-power equipment that allows us to produce high-quality packaging in any print runs.

in packaging creation

service

Satisfied customers

production

Bespoke packaging - shape, sizes and design

We create original and memorable boxes out of cardboard. Depending on the features of the product, your wishes and the budget, you can order the production of boxes of any shape and in any implementation.

Corporate style carries a built-in image and concept of the trademark. ATTOLIS has large fleet of modern equipment, and we use all kinds of modern technologies in the production of customized boxes:

Digital printing ATTOLIS offers digital full color printing for branding cardboard boxes for honey jars, sweets, cosmetics, soaps and other products of suitable size. We produce such packaging in small and medium runs. Pros: Silk-screen printing Today the technology is widely used in the printing industry. ATTOLIS company performs silk-screen printing on paper, cardboard, corrugated board, plastic and other materials. Features You can create an image using one color or several different colors, you can make a metallized or fluorescent image. For each color, its own stencil grid is created, the cost of silk-screen printing depends on the number of printing colors. Offset printing Today this technology is widely used in printing houses. ATTOLIS offers qualitative offset printing on boxes and packaging. Our experts will impliment any ideas of the client, make an unusual design for an individual order. We use offset printing to produce full color, durable corrugated boxes. Printing is not applied directly to corrugated cardboard, but to cardboard sheets. We use the laminating method on our special equipment - we glue cardboard with full-color offset printing to corrugated cardboard, cut it to shape, fold ready-made durable colorful boxes. Features Pros: Embossing ATTOLIS has all the necessary equipment for foil stamping and hot stamping, which allows us to implement different customer ideas in packaging decoration. When processing foil stamping, a foil is laid and pressed between the metal plate and the material, a metallized imprint remains on the material. For stamping we can use foil: Dyed embossing, i.e. embossing on print, is often used for the production of branded packaging. Additionally, selective UV varnish can be used, then the print will be even more voluminous. Features For one relief print 2 cliches are needed, which will compress the material from the front and back sides. The demand for this type of printing services is constantly growing in the field of business and advertising. Often in the manufacture of packaging and printing, printing is not used at all, all images and texts are applied by hot stamping and foil stamping. In addition to relief stamping and foil stamping, we also perform Silk Foil stamping without clichés. Silk Foil allows us to get an eminent image in the color of bronze, gold, silver, which is not depressed on the back. UV Coating In case of packaging branding by application of spot UV coating, the logo is applied with a transparent ultraviolet material, which makes it possible to highlight the brand name, gives it an overflow effect, but does not make it too catchy. To obtain a more colorful image, the logo can be printed by offset or digital printing with further UV varnish coating. An embossed, tactilely perceptible picture is provided by applying a "high" UV varnish. UV varnish can highlight not only the logo, but also other elements: illustrations, lines, company name. Adding glitter to the varnish allows to obtain a glitter material that will provide shine and attractiveness to the packaging design elements. Features Also UV-varnish can be matte - Soft Touch coating gives velvetiness to surface of printed products. The application of a special varnish provides: The use of UV varnish allows to create truly exclusive products.

Digital printing - transferring an image onto cardboard or paper using a laser, inkjet printer or printing machine. Application of paint directly to the sheet does not require longtime and expensive preparation. It is the ideal solution when for producing small runs of compact packaging boxes under tight deadlines.

Minuses:

Silk screen printing is a modern type of screen printing, which is performed using a special mesh. The thick paint under the pressure of the squeegee hits the surface through the holes of the mesh, on which the stencil of the future image is created. The print is dried with hot air and special lamps.

The screen-printing method is used for branding the packaging, applying prints, text, illustrations. This method allows you to obtain clear, high-quality printing keeping the original color of the image at the background of any color. So the brand logo printed on the cardboard packaging will remain in the corporate color, no matter what shade the background of the packaging is. Silk screen allows you to apply matte, glossy, complete or spot UV varnish.

Offset printing is a technology that involves applying an image to paper or cardboard by transferring it through special rollers. This method requires significant time and money, but the image quality is high.

Offset printing guarantees accurate color reproduction, contrasts and smooth color transitions.

Minuses:

Embossing is a creation of a sculptured image on a printed material by compressing it between cliches. Cliches for embossing are made according to the layout, in cliches the necessary shapes are cut out, they will leave an impress on paper or cardboard. The relief of the image can be eminent on the front side (embossing), or depressed (debossing).

For embossing, it is necessary to order the production of metal forms (cliches), their cost is calculated depending on the area of the embossed elements.

UV coating technology gives printed products a gloss and matte finish without lamination. Matte or glossy varnish can be applied to the entire surface of the product or selectively to make certain elements more noticeable.

Ultraviolet varnish has a high gloss, dries quickly, and is resistant to chemical and physical stress.

Variety of printing techniques allows us to create design options for packaging taking into account all the customer's wishes. On the outside of the box, you can put not only a brand sign, but also a slogan, print, and other corporate attributes.

Stages of creating kraft boxes

To make the kraft box customized to your goods and purposes, please determine the dimensions of the package, taking into account the size and weight of what will be packed in it.

for product creation

We produce packaging according to the layout provided by the customer, and make layouts based on the customer's materials.

Once the design is selected, decide on the print run. Remember, the larger the print run you order, the lower the cost of each box.

If you are satisfied with everything, then in the near future you will receive branded boxes with a printed logo. We print logos and texts on the boxes using full-color printing and various techniques - foil stamping, UV coating.

Order packaging from Attolis

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

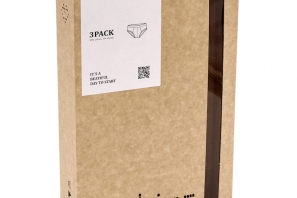

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

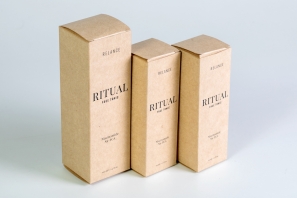

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

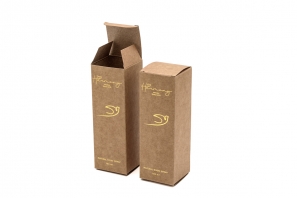

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

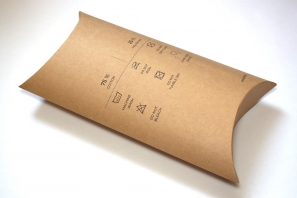

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |

The material is very popular for packaging textiles, gifts, jewelry, confectionery, bottles, flowers, handmade products, souvenirs, printed products. Customers usually favor one of the common shapes of kraft boxes: square, hexagonal, round, rectangular, shaped or trapezoid. Kraft cardboard boxes can be personalized in a variety of ways such as adding a brand logo, using unique shapes and design elements.

Where are kraft boxes used?

What shape of kraft boxes do you produce?

How to personalize kraft cardboard boxes for a brand or product?