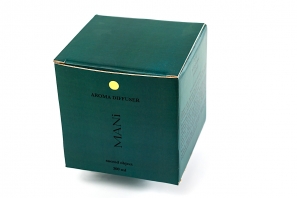

Premium printed corrugated cardboard packaging

Interesting product design with attention to detail plays an important role in business development. Beautiful packaging made of corrugated cardboard with printing will have a positive effect on visual perception, and hence the level of loyalty to the product. ATTOLIS will produce boxes in the required format, according to specified requirements, and most importantly, taking into account the characteristics of the goods for which they are intended.

All products are made to order.

More examples

Hide

More examples

Hide

Types of corrugated packaging

Modern equipment and an experienced team allow us to create packaging in a variety of shapes, styles and sizes. This has made it possible to interact with different business sectors: suitable branded boxes will be created for each product – comfortable, eye-catching, with an emphasis on the advantages of the product. There are several types of designs.

Self-assembled boxes

Easy to transform, do not require additional tools or glue for assembly, and most importantly, take up minimal free space when unfolded. Branded boxes made of corrugated cardboard are ideal for gift boxes, product sets and are suitable for any product - from textiles and cosmetics to oversized industrial goods. Also, such boxes are convenient for sending goods by mail; they are strong enough and do not require additional packaging.

Boxes lid-bottom

A universal solution for small, sophisticated items. It consists of separate parts for the top and bottom, which simplifies their assembly, and most importantly makes it easy to open or close the box. Most often, this option is used for souvenirs, watches, jewelry and similar categories of goods.

Gift boxes

Packaging made of cardboard or corrugated cardboard with a logo is designed in the company’s corporate style; in addition, various post-printing processing methods can be used - applying UV varnish, glitter varnish, embossing or foil stamping, glossy or matte lamination. To complete the design of gift packaging, you can order branded paper, satin or grosgrain ribbon with a logo from ATTOLIS.

in packaging creation

service

Satisfied customers

production

Style and aesthetics: types of printing

Corrugated box – a universal solution that protects goods during transportation and also becomes part of the brand image. The following printing methods are used to decorate the outer part of the packaging:

- Silk screen. A technique in which paint is applied to a surface using a centrifugal roller through a stencil. This gives the print high color stability and color saturation. A good choice if you need a drawing in bright, rich shades: the image quality will be impeccable, and the color of the image will be preserved even on the surface of brown cardboard..

- Laminating. Full Color Printing: Micro-corrugated or corrugated boxes will be durable with any full color printing. With the laminating method, a sheet of printed cardboard is glued to a sheet of corrugated cardboard. This method provides additional strength and attractive appearance, which is why it is widely used for high-quality branded packaging.

The choice between silk-screen printing and laminating depends on the specifics of the task at hand, as well as the key design idea. Experienced consultants will tell you in detail about the features of each technique in order to choose the best option.

Rigidity of the corrugation layer

To produce dense, practical boxes that allow you to effectively demonstrate the products being sold, two types of materials are used: micro-corrugated cardboard – for light, small goods, corrugated cardboard – for heavy products weighing from 5 kg. The following categories are distinguished by thickness:

- N – minimum;

- G – flexible micro-corrugated cardboard with a layer of corrugation no more than 0.8 mm;

- F – corrugation up to 1.2 mm;

- E – the most popular option with corrugated layer up to 1.8 mm.

Branded custom corrugated cardboard boxes are used in various areas of business due to their versatility, reliability, and environmental friendliness. This is an effective packaging that will provide convenient transportation and storage of goods, and most importantly, will become a useful marketing tool designed to increase brand awareness and stimulate consumer demand.

Where are these boxes used

Dense, stylishly designed containers can be used for packaging various product categories:

- food;

- desserts, confectionery;

- products for children;

- small electronics;

- perfumery;

- jewelry;

- jewelry;

- souvenirs;

- home textiles;

- bed linen;

- cosmetics for face or body care;

- elite alcoholic drinks.

A corrugated cardboard box with a pattern and the right design is suitable for different types of products. After the final request is formed, details will be agreed upon, a project will be developed – and the ATTOLIS team will promptly begin its implementation.

Printing capabilities

At the final stage, a batch of corrugated cardboard packaging acquires its uniqueness due to additional decorative elements that can be used in the design:

- Figure cutting. Will make it possible to create a variety of shapes and images on the surface. This allows you to implement original, creative design ideas that distinguish the brand from its competitors. And the basic product can easily turn into a gift option.

- Installing eyelets or handles. Plus during transportation, and also a good opportunity to demonstrate customer care through attention to detail.

- Lamination. Dense protective coating, which can be glossy or matte. Available in a special Soft Touch design, the velvety surface is pleasant to the touch, allowing you to combine visual and tactile interaction with the product to impress potential buyers.

Printed corrugated cardboard boxes can be additionally decorated with glitter varnish or embossing – Optimal solutions will be offered for each type of packaging.

Order a package from ATTOLIS

| Appearance | Manufacturing Material | Scope of Application |

|---|---|---|

|

||

| Self-assembling boxes | cardboard, corrugated fiberboard, designer cardboard 200 mg (brand: T-22 E-wave) | packaging for food products; boxes for confectionery; children's goods packaging; for small appliances |

|

||

| Lid bottom | laminated cardboard, laminated corrugated cardboard, binding cardboard, micro-corrugated cardboard brands: T-22, T-24 (E-wave) | perfume packaging; boxes for jewelry; confectionery; gift products; bed linen |

|

||

| Penal boxes | thin or thick cardboard (craft, plain, colored, or printed), cellulose cardboard (brand: T-22 cardboard density 275 g/sq. m.) | packaging for gift products; confectionery; children's goods |

|

||

| Pillow boxes | Cardboard, brown kraft-catron (cardboard of 250 g/sq. m.) | sock packaging; jewelry or ornaments |

How to choose the box size

Packaging is selected in accordance with the characteristics of the goods for which it is intended. This will allow you to define the following parameters:

- length;

- width;

- height.

It is necessary to take into account the difference between the internal and external dimensions, which depends on the thickness of the corrugated wave. Correct calculations will help you order four-valve or self-assembled products with the required dimensions.

The importance of quality printing on cardboard boxes

The first impression plays a vital role: it determines the interaction between the consumer and the product. Custom corrugated cardboard packaging is a profitable and rational solution for a number of reasons:

- Investments in original design pay off in full due to the growing sales volume and, accordingly, profits. The main thing is to choose an attractive, interesting design.

- High-quality printing allows you to create detailed, accurate, colorful images. The combination of text and pictures is very advantageous, and most importantly contributes to brand recognition and the formation of a positive perception among potential buyers.

- The cost of production depends on printing methods, selected material, packaging dimensions, post-printing processing methods and circulation. The larger the circulation, the lower the cost per unit of packaging.

Investments in packaging will bring significant benefits in the future and will have a positive impact on profit growth. The main thing is to focus on quality: ATTOLIS will quickly complete the task in strict accordance with the specified requirements.